CASE STUDIES

We have a growing number of case studies from across the Advancing Manufacturing Cluster Builder programme which we'd like to share with you here. You can view all case studies or filter by specific Project.

If you'd like to find out more about any of the case studies listed on this page, please get in touch with us.

Project: Aerospace Digital Visualisation Suite (ADVS)

WB Alloy Welding Products Ltd (ADVS)

WB Alloy Welding Products Ltd design, manufacture and supply a range of high quality, high integrity products, for both welding and cutting applications, to the Oil and Gas, Nuclear, Marine, Renewables, Power Generation and Construction sectors.

Challenge

Expanding operations had led WB Alloys to purchase new premises which would provide for ongoing growth, as well as the addition of bespoke demonstration areas and dedicated laboratory space for specialist services. The company was keen to ensure all requirements could be adequately accommodated in the new facility and that the available space was optimised from both the operations and sales perspective. Additionally, WBA senior management wanted to engage all staff in the relocation process by sharing information across the team. To achieve these objectives, WBA approached ADVS for help with Digital Twin modelling.

Solution

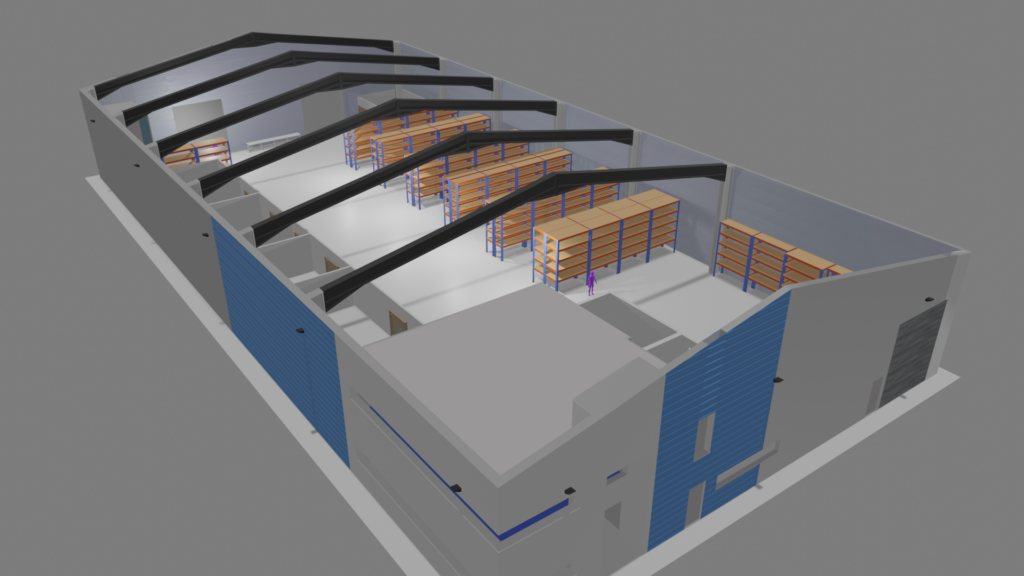

Working from 2-Dimensional drawings and photographs of the new facility, the ADVS team accurately 3-Dimensionally modelled the building fabric and spaces. This initial model was shared across all WBA staff, allowing them to support images and pictures with a volumetric construct. They then spent time with WBA, providing various iterations of layouts until a well-optimised solution was achieved.

A key feature of this project was the transfer of 3D Modelling capability to WBA. Their senior management team now understands the benefit of developing their own modelling capabilities as a method of providing valuable insight to any future process, function or layout changes. Throughout the project, ADVS worked closely with WBA personnel to share the software and build their 3D modelling capability. As a result of this, WBA staff now have the necessary skills and have taken responsibility for the ongoing development of their Digital Twin.

Colin Allan, Non-Executive Director Operational Projects, commented:

“The visualisation service provided by the ADVS team was immensely valuable to us, in terms of both time and cost. Prior to us considering any physical movement, the ADVS team provided us with an accurate digital twin of our new facility allowing us to easily make changes and determine impacts. Further to realising the immediate digital capability benefits, the experience and networks opened to us through working with the ADVS team have greatly assisted us with research and development opportunities outwith the field of visualisation.”